Product Details

The quality of diesel fuel remains a significant and unavoidable challenge. Even when allowing for a period of natural settling prior to refueling, the fueling process remains vulnerable to contamination from multiple variables including ambient conditions, cleanliness of transfer tools, and tank hygiene standards.

Such contamination vectors can thus compromise fuel integrity, ultimately causing damage to engine components and other critical systems. This operational reality fundamentally necessitates the indispensable role of diesel fuel filters in intercepting particulate contaminants.

Water contamination can disrupt oil film integrity in fuel injection, causing boundary lubrication conditions. This accelerates wear rates. The presence of water in diesel fuel systems induces progressive operational degradation.

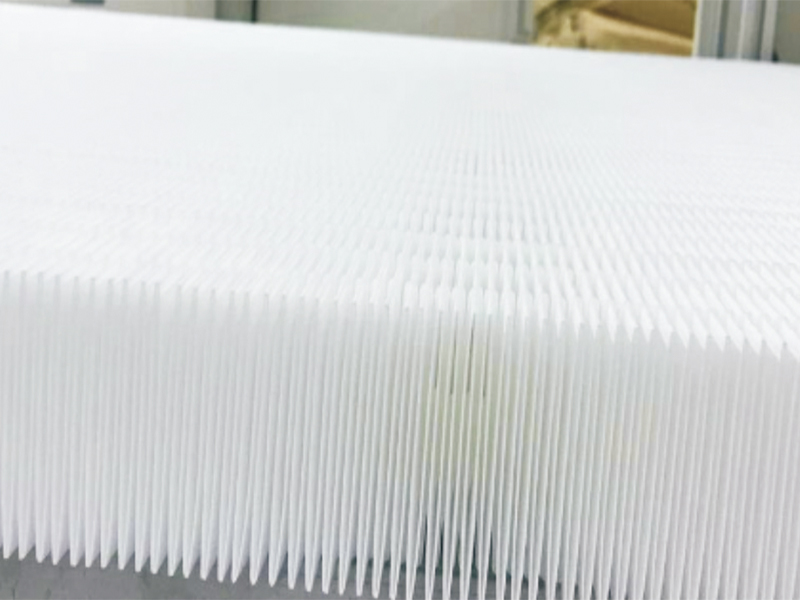

Our fuel filter products are micro glass, can be made of single layer, dual layers or multi layers. Our products can also deliver fuel water separation through shedding or coalescing. The product composition can be depending on customers’ needs:

Cellulose + Melt blown + scrim

Cellulose + glass fiber + scrim

PET + melt blown + glass fiber + scrim

We satisfy the test of ISO19438, ISO4020, ISO16332, SAE 1488.

Product Code | FB0266 | FB0566 | RH1066 | RH2066 | ||

Composition | PET double side – gradient glass layers | PET double side – gradient glass layers | PET double side – gradient glass layers | PET double side – gradient glass layers | ||

Basis Weight | g/m2 | TAPPI T410 | 210 | 210 | 210 | 210 |

Thickness | Mm | TAPPI T411 | 0.79 | 0.79 | 0.80 | 0.82 |

Air permeability | l/m2s | ASTM D737 – 200Pa | 40 | 95 | 178 | 304 |

PMI mean flow pore size | Μm | ASTM F316 | 2.8 | 4.3 | 8 | 19 |

Dry burst strength | kPa | TAPPI T403 | 341 | 326 | 337 | 283 |

Tensile strength – MD | kN/m | TAPPI T494 | 1.23 | 1.15 | 0.973 | 0.82 |

Tensile strength – CD | kN/m | TAPPI T494 | 0.57 | 0.43 | 0.391 | 0.37 |

Gurley stiffness – MD | Mg | TAPPI T494 | 4500 | 4600 | 5800 | 5500 |

Multi-pass rating β(C)75 (0.7 l l/min) | % | ISO 19438 | <4 | 4.1 | 9.8 | 20.3 |

Efficiency @ 4 micron | % | ISO 19438 | 99 | 98 | 88 | 54 |

DHC by multi-pass (0.7 l/min) | g/m2 | ISO 19438 | 230 | 270 | 316* | 320 |

Basis weight

Basis weight

Emissions control

Emissions control