Product Details

Filtration for hydraulic and lubrication systems

The hydraulic system and lubrication system have extremely high requirements for the particulate matter and water content in hydraulic oil and transmission oil. Excessive particles and moisture will degrade the performance of lubricants, leading to a series of issues such as gear wear, pitting corrosion, bearing failure, and sticking of hydraulic cylinder pumps/valves.

Therefore, hydraulic filters play a critically important role throughout the entire process by maintaining oil cleanliness and preventing contamination-related failures.

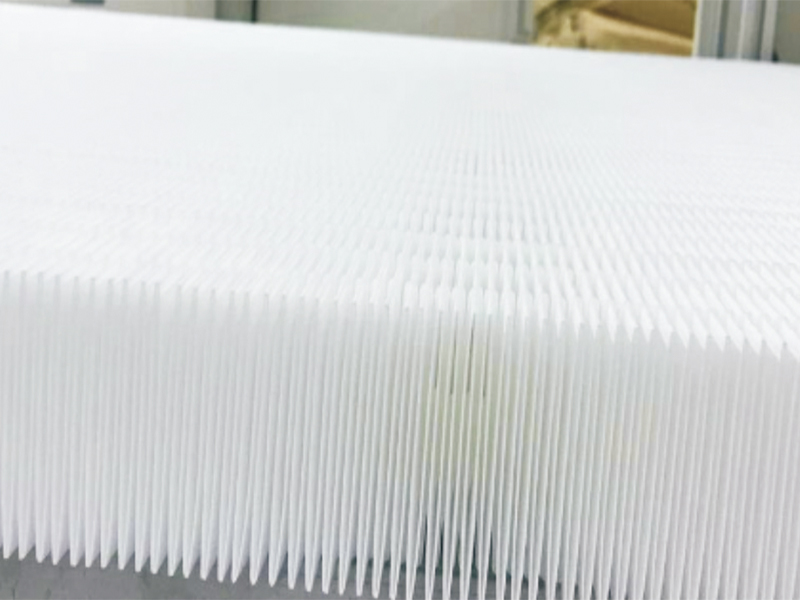

Our product is a microglass fiber medium, which laminates PET non-woven on both sides, with either single layer or gradient layers available. It’s suitable for a variety of liquid. It features

Robust dual phase materials with high dust holding capacity

Low pressure drop and high strength

Single phase/ dual phase/ single layer/ multi layer

Lower basic weight, thinner media, more filtration area

Full synthetic for long service interval

Product Code | FB0201H | FB0601H | FB1001H | FB2001H | FB3001H | FB4001H | FB1001HG | FB0601HG | ||

Composition | PET double side | PET double side | PET double side | PET double side | PET double side | PET double side | PET double side – gradient glass layers | PET double side – gradient glass layers | ||

Basis Weight | g/㎡ | TAPPI T410 | 107 | 107 | 107 | 107 | 108 | 108 | 139 | 140 |

Thickness | mm | TAPPI T411 | 0.41 | 0.42 | 0.42 | 0.42 | 0.45 | 0.46 | 0.58 | 0.58 |

Air permeability | l/m2s | ASTM D737 – 200Pa | 40 | 106 | 243 | 433 | 656 | 850 | 155 | 93 |

PMI mean flow pore size | μm | ASTM F316 | 2.4 | 6.3 | 11.3 | 19.3 | 29 | 38 | 9.7 | 5.8 |

Dry burst strength | kPa | TAPPI T403 | 319 | 304 | 272 | 268 | 265 | 230 | 307 | 354 |

Tensile strength – MD | kN/m | TAPPI T494 | 1.13 | 1.06 | 0.68 | 0.69 | 0.71 | 0.66 | 0.99 | 1.28 |

Tensile strength – CD | kN/m | TAPPI T494 | 0.43 | 0.37 | 0.22 | 0.28 | 0.21 | 0.20 | 0.38 | 0.46 |

Gurley stiffness – MD | mg | TAPPI T494 | 1900 | 2100 | 2000 | 2000 | 2300 | 1800 | 4900 | 4800 |

Multi-pass efficiency β(C)200 (5.0 l/min) | % | ISO 16889 | 1 – 3 | 5 - 8 | 10 | 20 | 30 | 40 | 11.3 | 5.5 |

DHC by multi-pass (5.0l/min) | g/m2 | ISO 16889 | 70 | 73 | 80 | 113 | 172 | 210 | 166 | 153 |

Basis weight

Basis weight

Emissions control

Emissions control